1. Kirish

The VEVOR 801D Battery Spot Welder is a high-performance capacitor energy storage pulse spot welder designed for precise welding of pure nickel strips ranging from 0.1mm to 0.3mm. It is suitable for various applications including battery assemblies, metal hardware, and electronic components. This manual provides essential information for the safe and effective operation of your device.

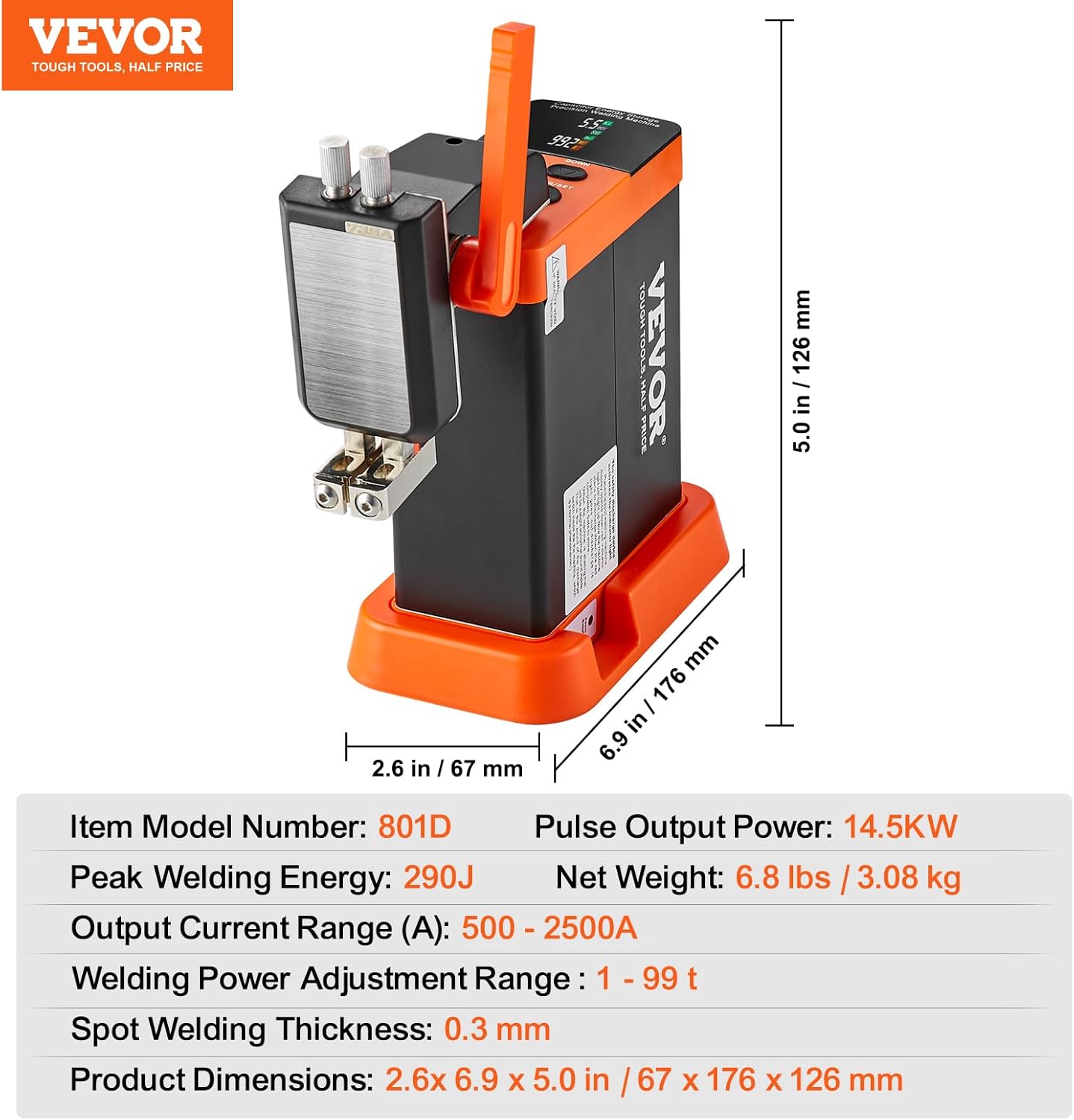

Image 1: VEVOR 801D Battery Spot Welder with 73B Welding Pen and accessories.

2. Xavfsizlik ma'lumotlari

Please read and understand all safety warnings and instructions before operating this device. Failure to follow these instructions may result in electric shock, fire, serious injury, or property damage.

- Always wear appropriate personal protective equipment (PPE), including safety glasses and gloves, when operating the spot welder.

- Ish joyi yaxshi ventilyatsiya qilinganligiga va yonuvchan materiallardan xoli bo'lishiga ishonch hosil qiling.

- Qurilmani nam yoki d holda ishlatmangamp sharoitlar.

- Bolalar va ruxsatsiz xodimlarni operatsiya maydonidan uzoqroq tuting.

- Har qanday texnik xizmat ko'rsatish yoki sozlashni amalga oshirishdan oldin quvvatni o'chiring.

- Avoid touching the welding electrodes or welded materials immediately after welding, as they will be hot.

- Use only VEVOR-approved accessories and replacement parts.

3. Paket tarkibi

Quyida sanab o'tilgan barcha narsalar paketingizga kiritilganligini tekshiring:

- 1 x Spot Welder (801D Main Unit)

- 1 x 73B Spot Welding Pen

- 1 x 73SA Lower Head

- 1 x oyoq pedali kaliti

- 1 x adapter

- 1 x Baza

- 1 x 18650 Six-Jaw Fixture

- 4 x Fixed Head Welding Needles

- 1 x Flathead Screwdriver

- 1 x Small Hex Wrench

- 1 x foydalanuvchi qo'llanmasi

- 1 x Pressure Adjustment Wrench

- 1 x Cross Screwdriver

- 2 x 73B Welding Pen Needles

- 1 x olti burchakli kalit

- 100PCS x Nickel Samples (50PCS each of 8mm and 4mm)

Image 2: All components included with the VEVOR 801D Battery Spot Welder.

4. Mahsulot tugadiview

The VEVOR 801D is a compact and powerful spot welder featuring a 14.5KW pulse output and 290J peak welding energy. It incorporates super energy-gathered pulse welding technology for efficient and consistent results.

4.1 Asosiy blok

The main unit houses the capacitor energy storage system and the intelligent LED panel display. This display provides real-time welding parameters, including charging voltage, actual welding current, and energy grade.

Image 3: Close-up of the advanced LED panel display showing welding parameters.

4.2 Welding Pens

The device includes a 73B welding pen and a 73SA handle-push welding arm, offering flexibility for various welding tasks. The welding pens are designed for precise application of welding energy.

Image 4: Illustration of the VEVOR 801D's powerful pulse output and peak welding energy.

5. Sozlash

Follow these steps to set up your VEVOR 801D Battery Spot Welder:

- Komponentlarni o'rash: Paketdagi barcha narsalarni ehtiyotkorlik bilan olib tashlang va paket tarkibidagi narsalar ro'yxati bilan taqqoslang.

- Attach Feet (if applicable): If separate feet are provided, attach them to the bottom of the main unit for stability.

- Connect Welding Pens: Insert the connectors of the 73B welding pen or 73SA handle-push welding arm into the designated ports on the front panel of the main unit. Ensure a secure connection.

- Connect Foot Pedal (Optional): If using the foot pedal for manual welding mode, plug its connector into the 'Foot Switch' port on the main unit.

- Quvvat adapterini ulang: Plug the power adapter into the 'Power Supply' port on the rear of the main unit, then connect the adapter to a suitable power outlet.

- Yoqilgan: Flip the power switch to the 'ON' position. The LED display will illuminate.

Image 5: The 73B welding pen connected to the main unit and ready for use.

6. Foydalanish bo'yicha ko'rsatmalar

The VEVOR 801D offers two welding modes and adjustable power settings for optimal performance.

6.1 Adjusting Welding Parameters

Use the intelligent LED panel display to monitor and adjust welding parameters:

- Welding Power: Adjust energy levels within the 1-99t range using the control knob or buttons on the panel.

- Kondensator Voltage: Monitor the charging voltage ekranda aks etadi.

- Actual Welding Current: View the real-time welding current during operation.

6.2 Payvandlash rejimlari

The device supports two distinct welding modes:

- AT Mode (Automatic Welding): Ideal for quick, large-scale welding tasks. The device automatically triggers the weld when the electrodes make proper contact with the material.

- MT Mode (Manual/Pedal-Controlled Welding): Allows for precise, fine-tuned welding processes. This mode typically requires the use of the foot pedal to initiate the weld.

Image 6: Visual representation of the two welding modes: Automatic (AT) and Manual (MT).

6.3 Payvandlash jarayoni

To perform a weld:

- Prepare the materials to be welded, ensuring they are clean and properly aligned.

- Select the appropriate welding mode (AT or MT) and adjust the energy grade (1-99t) based on the material thickness and type.

- Position the welding pen electrodes firmly against the nickel strip and the battery terminal.

- If in AT mode, the weld will automatically trigger. If in MT mode, press the foot pedal to initiate the weld.

- Hold the electrodes in place briefly after the weld to allow for cooling.

- Inspect the weld for strength and quality. Adjust settings as needed for subsequent welds.

Image 7: Demonstrating the precise welding capability for 0.1-0.3mm pure nickel strips.

6.4 Ilovalar

The VEVOR 801D is suitable for:

- Battery pack manufacturing (e.g., 18650, 26650, 32650 cells)

- Welding pure nickel strips to battery terminals

- Joining metal hardware components

- Repairing and assembling electronic components

Rasm 8: Masalanamples of versatile applications for the spot welder.

7. Xizmat ko'rsatish

Regular maintenance ensures the longevity and optimal performance of your spot welder:

- Tozalash: Keep the main unit and welding pens clean and free of dust, debris, and welding spatter. Use a dry, soft cloth.

- Elektrod tekshiruvi: Regularly inspect the welding electrodes for wear or damage. Replace them as needed to maintain welding quality.

- Kabelning yaxlitligi: Check all cables and connections for signs of wear, cuts, or loose fittings. Replace damaged cables immediately.

- Saqlash: Store the device in a dry, cool place away from direct sunlight and moisture when not in use.

8. Muammolarni bartaraf qilish; nosozliklarni TUZATISH

If you encounter issues with your VEVOR 801D, refer to the following common problems and solutions:

- Quvvat yo'q: Ensure the power adapter is securely connected to both the unit and the power outlet, and the power switch is in the 'ON' position. Check the power source.

- Weak Welds: Increase the energy grade setting. Ensure electrodes are clean and have good contact with the material. Verify material thickness is within the recommended range (0.1-0.3mm for pure nickel).

- Haddan tashqari qizib ketish: Allow the unit to cool down. Ensure adequate ventilation around the device. Reduce continuous welding cycles if necessary.

- Inconsistent Welds: Check electrode tips for wear and replace if necessary. Ensure consistent pressure and contact during welding. Verify material cleanliness.

9. Texnik shartlar

| Xususiyat | Spetsifikatsiya |

|---|---|

| Model raqami | 801D |

| Pulse Output Power | 14.5 kVt |

| Payvandlashning yuqori quvvati | 290J |

| Chiqish oqimi diapazoni (A) | 500 - 2500A |

| Welding Power Adjustment Range | 1 - 99t |

| Spotli payvandlash qalinligi | 0.1-0.3mm (Pure Nickel) |

| Element og'irligi | 6.8 funt / 3.08 kg |

| Mahsulot o'lchamlari | 2.6 x 6.9 x 5 dyuym / 67 x 176 x 126 mm |

| Quvvat manbai | AC |

| jildtage | 120 volt |

Image 9: Key specifications and dimensions of the VEVOR 801D Spot Welder.

10. Kafolat va qo'llab-quvvatlash

For warranty information, technical support, or any inquiries regarding your VEVOR 801D Battery Spot Welder, please visit the official VEVOR support websayt:

Please have your model number (801D) and purchase information ready when contacting support.